Organizers

Energy Systems Network

Energy Systems Network (“ESN”), a branded initiative of the Central Indiana Corporate Partnership (“CICP”), is a non-profit industry consortium of companies and institutions focused on the development of the advanced energy technology sector.

ESN was founded in 2009 with the explicit mission to accelerate the pace of energy and transportation technology development and commercialization in Indiana and beyond. Through ESN, companies and institutions from across Indiana and around the world – including Cummins, Duke Energy, Delphi, Toyota, Bolloré, ITOCHU, Toshiba, Vectren, MISO, Purdue, Ivy Tech, Notre Dame and many others – have worked to plan and implement an ambitious portfolio of diverse pilot projects that have showcased and advanced automotive innovation. This has included among other achievements:

The first and largest all-electric car sharing system in the nation

The largest electric bus fleet of any city in the U.S., and the first electric bus rapid transit line

The largest public fleet of plug-in vehicles of any municipality in the U.S.

The highest concentration of public charging infrastructure in the nation

The first commercial vehicle-to-grid communication validation

The first mobility-as-a-service (MaaS) public fleet contract

The first electric vehicle fast charging station powered by renewable energy

ESN is also a recognized thought leader and subject matter expert in the fields of energy and transportation. Recently, ESN released Emerging Mobility Technologies and Trends, a comprehensive review and discussion of the evolution of the transportation and mobility industry, from the 20th century’s orientation toward roadways and personal automobiles; to vehicles’ current advancements propelled by electrification, automation, and sharing; to the emergence of “micromobility” (such as bikes or scooters) and other functional modes and business models, including Mobility-as-a-Service (MaaS) models that offer a variety of transportation solutions based on the consumer’s specific needs through one platform.

In September 2019, ESN and board members Cummins Inc. and Purdue University launched a four-month pilot project in Indiana to evaluate an on-demand transit solution. The collaborative experiment, called Leaper X, includes a web-based mobile application powered by Cummins, and a small trial fleet of designated campus shuttles in addition to Purdue’s traditional campus buses. The piloting of the Leaper X platform helps advance what Emerging Mobility Technologies and Trends says will be a new “Mobility-as-a-System” landscape, whereby different modes, providers, and usage models are synthesized to improve travel.

For more information, visit: https://energysystemsnetwork.com/

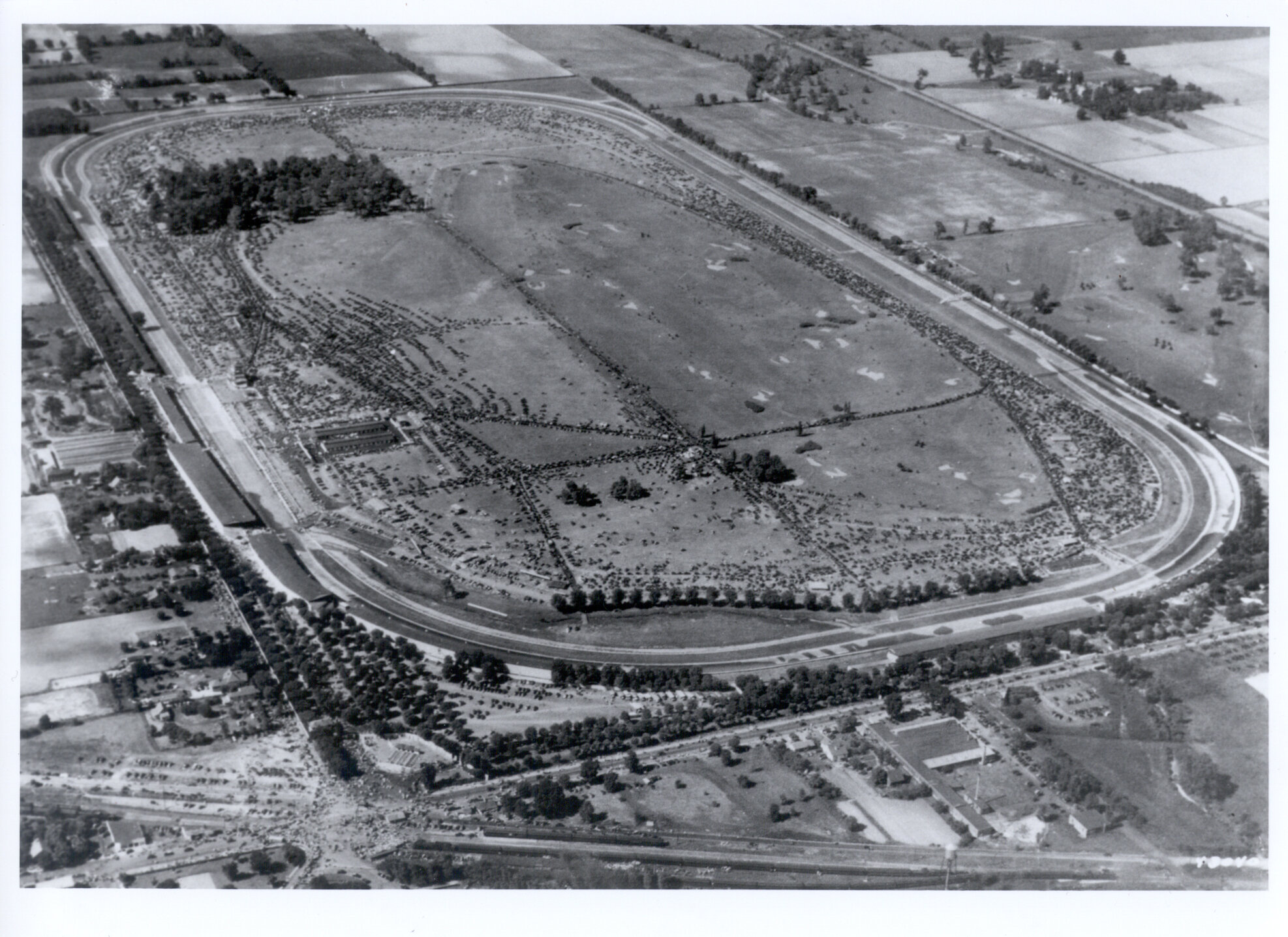

Indianapolis Motor Speedway

The Indianapolis Motor Speedway has been an incubator and proving ground for automotive innovation since it opened in 1909. The facility originally was designed as a test track for the burgeoning automotive industry in Indianapolis at the turn of the century, and innovation began with the inaugural Indianapolis 500 in 1911, when winner Ray Harroun equipped and used what is believed to be the first rear-view mirror in automotive history on his Marmon “Wasp” race car.

Over the years, countless automotive and motorsports breakthroughs have been fostered at IMS, especially those pertaining to safety. For example, the brick surface, one of the Speedway’s most treasured legacies that quickly lent the nickname “The Brickyard” to the venerable track when it was laid down in 1909, was installed in response to an acute need for greater safety.

When the original tar-and-crushed-stone surface proved too unstable during that first summer of racing in 1909, track co-founders Carl G. Fisher and James Allison took little time in deciding that paving bricks – more expensive but more robust than concrete – should be the surface of the future.

Another major innovation, for racing and the automobile industry in general, was crafted essentially out of desperation two years later. Ray Harroun and the Nordyke & Marmon team showed up for the inaugural Indianapolis 500 Mile Race with a single-seat car, the No. 32 “Wasp.” All other teams had two-seat cars which allowed a riding mechanic to be on board and serve as a second set of eyes. The cry went up that Harroun couldn’t see cars behind him, would therefore be a safety hazard when on track, and should be banned from racing.

Harroun and the team took a piece of mirror and framed it in steel, mounted it at the top of his range of vision, and the first-ever rear-view mirror was created.

Other “firsts” for racing that were perfected or came into being at IMS include the first use of a Pace Car (1911), what is believed to be the first mass rolling start of a race (1911), the first use of four-wheel hydraulic brakes (1921), the first installation of color warning lights (1935), the first mandatory use of helmets (1935) and the first use of crash-data recorders (1993).

As the 21st century dawned on the Speedway, arguably the greatest invention to protect drivers in a high-speed crash, the SAFER (Steel and Foam Energy Reduction) Barrier, was applied to the track’s four turns, in May 2002.

The SAFER Barrier is constructed in 20-foot modules. Each module consists of five rectangular steel tubes, welded together, to form a unified element. The modules are connected with internal steel splices, and bundles of 2-inch-thick sheets of extruded, closed-cell polystyrene are placed between the concrete wall and the steel tubing modules.

The barrier was developed by the INDYCAR and the University of Nebraska-Lincoln’s Midwest Roadside Safety Facility beginning in 1998. NASCAR joined in the development of the project in September 2000.

On Opening Day of the 2002 Indianapolis 500, the Speedway once again became the laboratory for real-life safety research and discovery. Robby McGehee became the first driver to hit the SAFER Barrier in practice. The severity of the crash could have resulted in serious consequences, but McGehee suffered only minor injuries. The barrier also was in place for the 2002 Brickyard 400 and United States Grand Prix, and every event since.

The SAFER Barrier was removed from the Speedway’s walls in August 2004 to make way for a complete repaving of the oval. A second-generation version of the SAFER Barrier was installed in spring 2005.